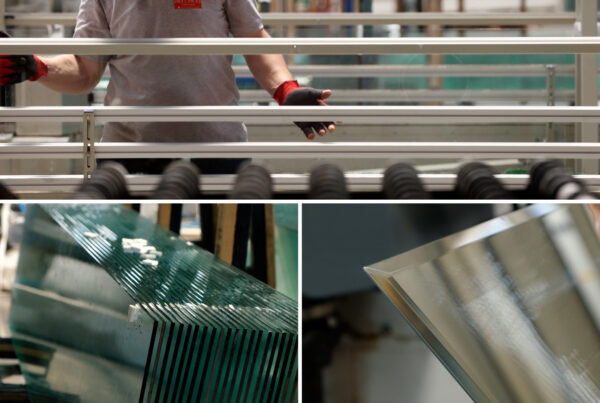

Laminated glass is produced by joining two or more glass plates together under heat and pressure with the help of colored or colorless special adhesive polyvinyl butyral (PVB) layers. It reduces the risk of injury by holding the pieces in place in case of breakage. Due to this feature, it is considered as laminated safety glass. Laminated glass is also a correct choice in terms of preventing or delaying unwanted transitions from one side to the other. Lamination is a standard and typical solution for the inner glasses of sloping or overhead glazing. Laminated glass can be created with insulated glass units (ISICAM®), colorless, colored from the batch, coated and tempered glasses. Laminated glass is also useful in terms of preserving the natural colors of items for a longer time with low UV permeability and noise control. Our stock includes 4+4 and 5+5 laminated thicknesses.